Enhance Your Product Packaging Process With a Dependable stretch wrapping machine for Optimal Performance

In the complicated globe of logistics, an efficient product packaging procedure is an important element that can substantially influence a firm's bottom line. The consolidation of a trustworthy stretch wrapping machine not only optimizes performance yet likewise ensures the integrity of items during transit - stretch wrapping machine.

Recognizing the Duty of a stretch wrapping machine in Product Packaging

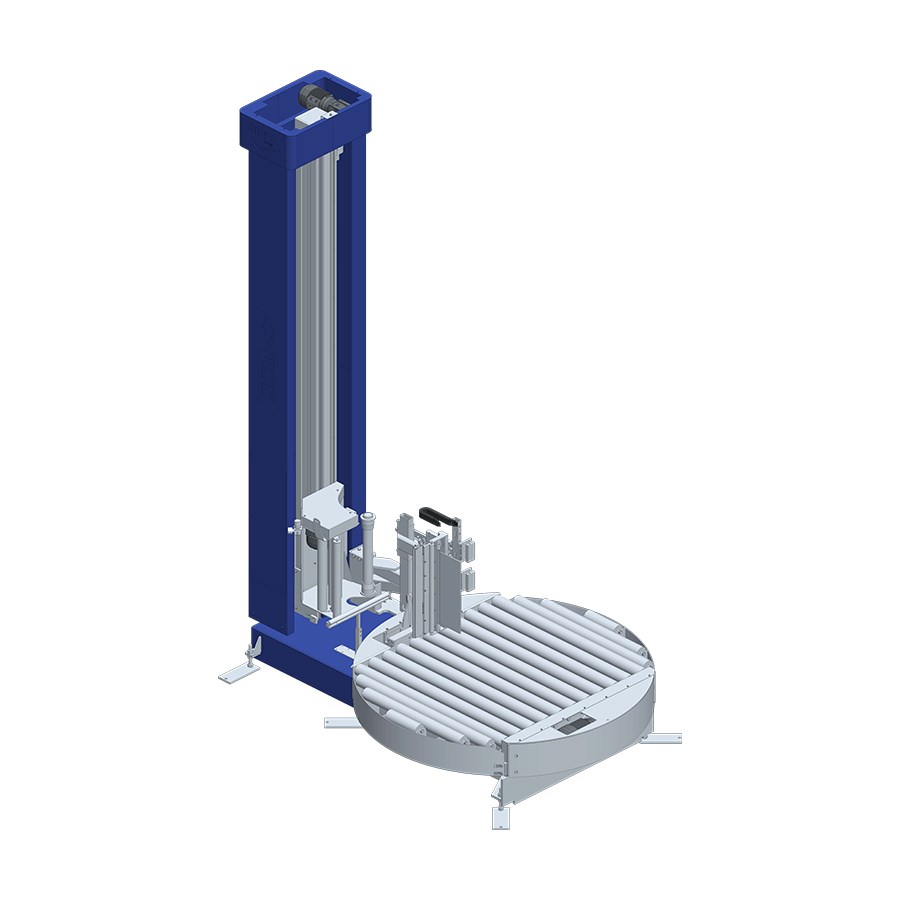

Ensuring product security during transportation, a stretch wrapping machine stands as a crucial possession in the packaging sector. Its main function rotates around enveloping things in a protective layer of film, consequently maintaining product honesty and minimizing damage risks during transport.

The equipment's procedure is complex yet efficient. Item are positioned on a turning base while the movie is unwinded from a set roll. As the turntable spins, the film is used evenly over the things, ensuring total insurance coverage.

This device's importance extends beyond plain covering. stretch wrapping machine. It boosts the stacking security of items, decreasing the chance of accidents. Further, it safeguards items from dirt, dampness, and other ecological variables, keeping their quality till they get to the customer

In significance, a stretch wrapping machine is a vital tool for organizations looking for to optimize their packaging procedure, secure their items, and improve their logistics operations. Its duty is essential to the effective and effective performance of the modern-day packaging industry.

When Selecting a stretch wrapping machine, secret Features to Think About.

When choosing a stretch wrapping machine for product packaging functions, a number of essential features warrant consideration. These consist of assessing the maker's performance, recognizing its load capacity, and assessing its longevity and maintenance demands. A notified decision joints on a detailed evaluation of these variables.

Although efficiency could not be the very first thing you consider when taking into consideration stretch covering equipments, it is a necessary factor that can substantially influence your product packaging procedure. A reliable machine can significantly minimize waste, lower expenses, and boost performance. When evaluating effectiveness, consider the machine's speed. A faster maker can wrap extra bundles in much less time, boosting your operation's output. Likewise, check for programmable setups, which can personalize the covering process to suit various items, decreasing unnecessary use of products. Additionally, an effective device must need minimal upkeep, ensuring continuous operation without regular disturbances. The maker's energy usage is one more vital element, as a device that utilizes less power can cut running costs. Remember, an effective machine assurances optimal efficiency.

The Influence of a Reliable stretch wrapping machine on Performance Levels

Spending in a trustworthy stretch wrapping machine can dramatically increase productivity levels in a product packaging procedure. These equipments automate the covering process, allowing for constant and efficient performance that surpasses hand-operated covering approaches.

A reliable device minimises downtime created by mechanical failings or upkeep demands. This makes sure a stable flow of job, stopping delays and backlog in the manufacturing chain. Premium stretch wrapping machines likewise have adjustable setups for different item types. This adaptability permits organizations to deal with a wide series of things without time-consuming manual adjustments.

In addition, these equipments require less human intervention, maximizing employees to focus on various other necessary jobs. This optimization of human resources can lead to an increase in general operational productivity.

Basically, a dependable stretch wrapping machine is a useful investment that can improve efficiency levels in a product packaging procedure, providing considerable benefits in source, effectiveness, and versatility exercise.

Ways in Which a stretch wrapping machine Reduces Waste

A stretch wrapping machine's function in waste reduction is considerable and diverse (stretch wrapping machine). Not only does it lessen product usage by successfully covering items, yet it additionally safeguards goods from damage throughout handling and transportation. This twin benefit lead to notable price financial savings and promotes sustainability in the packaging process

Minimizing Material Usage

Expense and Time Financial Savings: The Financial Advantages of a stretch wrapping machine

Furthermore, the equipment's consistent covering method decreases product damage, decreasing substitute costs and enhancing client contentment. Making use of a stretch wrapping machine likewise results in a much more foreseeable budgeting process, as the quantity of stretch movie used per pallet corresponds, unlike manual covering which can vary significantly.

Eventually, the cumulative financial savings in labor, materials, and possible product loss make the initial investment rewarding. In the lengthy term, companies can attain considerable economic benefits by integrating a stretch wrapping machine right into their product packaging process.

Final thought

Although performance might not be the initial point you assume of when considering stretch covering makers, you could try this out it is an essential variable that can considerably influence your product packaging process. The machine's energy consumption is one more essential factor, as a maker that makes use of less energy can cut operating prices. In addition, an equipment sustained by a thorough warranty and exceptional consumer solution can reduce prospective problems in keeping the device's optimal efficiency.To understand the ways in which a stretch wrapping machine decreases waste, one should first think about the innovative design of these equipments. In this method, stretch wrapping equipments not only improve the high quality of product packaging yet additionally cultivate a much more reliable and environmentally-friendly process, demonstrating their vital role in modern product packaging procedures.